FRYER systems

FRYER systems

Since 1968, GEM Equipment has been at the forefront of custom food processing equipment, specializing in advanced frying systems. We engineer industry-leading food processing solutions designed to maximize efficiency, performance, and product quality. As the global leader in frying equipment, we provide cutting-edge systems tailored to the specific needs of food manufacturers worldwide. From standalone machines to fully integrated processing lines, our equipment is built with precision engineering, stainless steel durability, and advanced Computational Fluid Dynamics (CFD) modelling for superior performance. Every fryer is designed to optimize oil flow, minimizing oil turnover while maintaining minimum oil volumes.

Our fryer solutions are unmatched. We offer the following frying series to meet and exceed your product frying needs.

French Fry Series

GEM built its first French Fry Fryer in 1985, successfully tapping into one of the largest markets in the world. Today, GEM designs, builds, and installs single and two-stage fryers based on small to large throughput capacities. For French Fries, batter-coated fries, and specially cut potato products, GEM French Fry Fryers deliver uniform product quality with consistent colour and texture.

GEM French Fry Fryers can be built for a wide range of throughput capacities. The fryers’ optimized oil flow and circulation control ensures consistent two-stage frying performance for uniform product quality along with perfect colour and texture. Keeping safety in mind, the specially designed fryer kettles eliminate dead spots and reduce fire hazards while increasing oil shelf life.

CO-PRODUCT FRYER SERIES

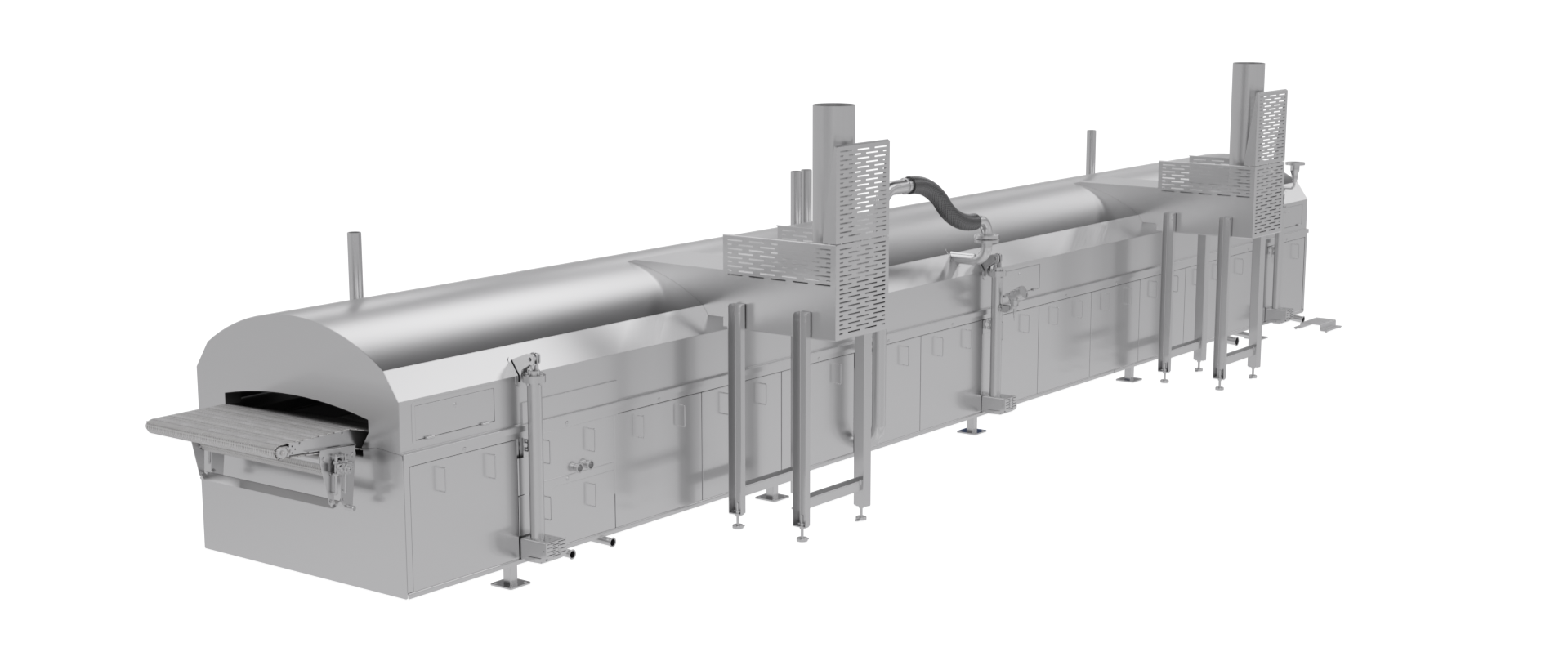

GEM Co-Product or Specialty Fryers are designed to handle various shapes and textures of formed products such as extruded potato specialties (hash browns, croquettes), dairy (cheese balls, cheese sticks), bakery (pizza crust, egg rolls), vegetable appetizers (jalapeno poppers, formed potato products, broccoli bites) and more. Angled inlets and specially engineered return headers offer optimal oil flow. The downdraft oil curtain option for formed patties ensures crisp top surface. A singulated layer of product avoids overlap and inconsistency, while the fryers’ robust construction enables longer cook time for higher efficiency. Precisely controlling temperature and oil flow, GEM Co-Product Fryers take care of every detail and are suitable for a variety of formed products.

Versafry SERIES

GEM VersaFry is our latest innovation in fryer design – engineered for maintenance, safety and durability. With the ability to handle a variety of product shapes, consistencies and textures, the VersaFry not only can handle Co-Product Appetizers but are exceptional with poultry (chicken nuggets, chicken strips), seafood (tempura shrimp, calamari, fish sticks) and delicate dough consistencies (doughnuts, strudels, pizza crust, egg rolls) including many other items that require precision frying.

The GEM VersaFry offers Operation and Sanitation Modes, highlighting attention to detail such as oil quality, fire prevention safety measures and cleanability.

Key Features

Adjustable Infeed Conveyor – Option in PEEK or Teflon material, its high-performance provides a smooth surface that withstands high oil temperature. This allows time for batter to set on the bottom of the product before being transferred to the metal conveyor

Main Conveyor – Engineered to be long lasting, reduce potential contamination, and is easy to splice

Hood Raise Screw Jack System – This unique function is used to raise the hood and conveyor belts out of the kettle, allowing for full checks during sanitation and maintenance

Oil Recirculation Pump - During recirculation, fresh oil can be added to heated oil, maintain oil levels and even temperature

Crumb Skimmer pulls in crumbs and oil from surface level while return belt implements Crumb Removal from bottom of kettle

Shared Features

Specially manufactured fryer belts are made with high wear and abrasion resistance properties

Scientifically designed oil filters extend oil life while maintaining high product quality such as the Hydro Cyclone and Paper Filter options

Custom hood lift mechanism and Clean-in-Place (CIP) system provide accessibility and cleanability

Fully Welded Floating Kettle designed for optimal durability, allows for expansion of steel while minimizing stress concentrations

Manufactured with safety and maintenance in mind, preventive fire solutions are integral in every fryer design, including fire suppression systems and minimal fire points

Engineering Ingenuity in Fryer Design

Demonstrating engineering ingenuity, GEM’s industry-leading fryers are manufactured with safety and maintenance in mind. For example, preventive fire solutions are integral in every fryer design, including fire suppression systems and minimal fire points. Every possible aspect is taken into account to ensure minimal risk—from kettle design to product guides to efficient waste collection and removal.

Low system oil volume is critical to achieving a high-quality finished product. At GEM, every fryer design undergoes Computational Fluid Dynamics (CFD) or flow modeling, to perform hypothetical analyses of the cooking operation of the fryer kettle to optimize product quality and cooking oil usage. As oil degrades due to heated temperatures for extended periods of time, GEM engineers can provide fryer oil design solutions for quality performance.

Custom Design for Efficient Solutions

Custom designed fryers and fryer systems are based on clients’ requirements—there are no two alike. From product type to geographical location, GEM engages with each customer, large or small, to meet expectations, be it retrofitting existing fryers to building complete fryers and fryer systems.

We believe that each customer is unique and important to GEM. From building the largest fryer in the world to designing specialty fryer systems for multiple product types, GEM prides itself in raising the bar. With durability and longevity in mind, GEM manufactures for tomorrow’s customers.

Lowest Cost of Ownership

Every fryer is built with robustness and longevity as top priorities, to provide customers with the lowest cost of ownership. By taking into account material wear and tear, GEM utilizes durable materials in its construction. For instance, its specially manufactured fryer belts are made with high wear and abrasion resistance properties. GEM’s scientifically designed oil filters and fryer kettles extends oil life while maintaining high product quality. With its custom hood lift mechanism and Clean-in-Place nozzles, GEM fryers provide accessibility and cleanability. Our experienced service and retrofit specialists can also help further maintain or extend the life of the fryer. For valued customers, our goal is to be part of the solution.