IQF TUNNEL FREEZERS

iqf tunnel freezers

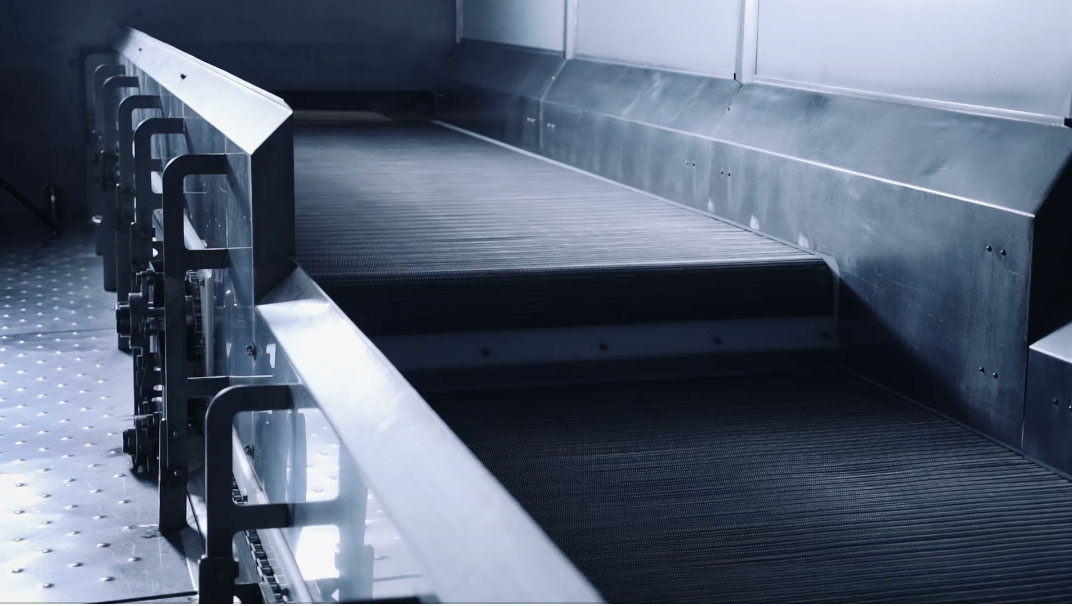

FPS’s range of Individual Quick Freeze (IQF) tunnel freezers implement a combination of air and mechanical fluidization techniques to ensure products like fruits and vegetables are efficiently and individually quick frozen with high quality.

Our Air Flow IQF technology ensures gentle handling by continuously lifting and separating products as they move through the tunnel. Using stainless-steel or perforated Intralox acetal belts, FPS brings years of in-depth experience according to each product type.

The combination of our IQF technologies with our hygienic design fundamentals results in a high-performance tunnel freezer satisfying the most stringent food safety requirements.

Features

External fan & thumper motors

Hygienic fully welded stainless steel construction

Gentle mechanically assisted fluidization

SynchroSD™ Sequential Defrost System for prolonged production runs

Recirculating Clean-In-Place (CIP) system

Slip-resistant sloped floors for effective drainage

Hygiene & Ease of Cleaning

With an embedded support structure, our fully welded wall and floor system allow motors and gearboxes to be mounted on the outside of the enclosure. This eliminates ancillary parts such as conduit and junction boxes to enhance cleanability.

We also remove redundant support structures inside the enclosure and elevate components off the floor to further reduce potential bacterial harborage points while creating easier and safer access for cleaning. Our recirculating Clean-In-Place (CIP) system provides repeatable full tunnel cleaning with an optional pasteurization step to meet the highest hygienic standards.

Maximized Yield with Superior Quality

To extend the tunnel freezer’s uptime, our SynchroSD™ Defrost System utilizes hot gas for synchronized sequential defrosting without impacting freezer performance or product quality.

Our centrifugal fans provide consistent air velocity control to ensure excellent handling, minimizing product blow-off and loss with low energy consumption. Mechanical agitation further improves the flow of product through the tunnel.

Reduced Maintenance Costs

Having our IQF tunnel freezer’s drives and motors mounted externally instead of placed in the tough internal environment extends their service life and reduces related maintenance.

Explore Our IQF Tunnels

CASE STUDY

INCREASED PEA PRODUCTION, MINIMAL DOWNTIME: FPS IQF TUNNEL FREEZER

Foodhills AB, a pea producer based in Sweden, significantly increased its pea production capacity by installing an FPS IQF tunnel freezer. The freezer’s SynchroSD™ Sequential Defrost and CIP systems eliminate daily downtime for defrosting and allow for effective cleaning, which has led to increased production output during the critical pea season.

“We have been up to 260 tons, but on average the daily production is a little over 200 tons. More production, less cleaning - that was our goal for the new line.”

— Jan Inge Nyström, Factory Manager | Foodhills AB