FPS Food Process Solutions Welcomes Southern Fabrication Works to Expand Rapidly Growing Portfolio

Vancouver, Canada – FPS Food Process Solutions (“FPS”), a global leader in turn‑key food processing solutions, announces the addition of Southern Fabrication Works (SFW) to further strengthen and expand its rapidly growing portfolio.

SFW is widely recognized for its expertise in designing and manufacturing custom industrial food processing equipment. Well established in the potato processing industry, the company has built a strong reputation for delivering integrated, high‑precision systems supported by meticulous engineering and seamless project execution.

By joining the FPS global family, SFW enhances FPS’s capabilities with advanced hydro-cutting systems, cutting‑edge water knife technology, innovative water recycling and waste‑handling solutions, and comprehensive plant engineering expertise. These additions further strengthen FPS’s ability to offer robust, end‑to‑end processing solutions to customers worldwide.

“The SFW family is super excited to partner with a progressive company such as FPS, who shares similar ideology. The FPS team has been extremely welcoming and respectful. We appreciate the value they place in all their partnerships and look forward to contributing to their global initiatives,” says Neil Justesen, President and Owner of Southern Fabrication Works.

“FPS has always aimed to provide full End‑to‑End solutions for our customers,” says Jeffrey Chang, President, FPS Food Process Solutions Corp. “The timing was right to join forces. We’re pleased to welcome a trusted and respected name into our group.”

###

About FPS Food Process Solutions

FPS Food Process Solutions is a global leader in turn-key food processing solutions, serving customers across six continents. Founded in 2010, FPS employs over 1,000 professionals worldwide and operates more than 1,280,000 ft² (119,000 m²) of space across 23 locations, including its Canadian headquarters, manufacturing facilities, and international sales offices. Through our subsidiaries and strategic partnerships, FPS delivers comprehensive, end-to-end processing solutions—providing a true “one-stop shop” for food processors around the world.

For more information, go to https://www.fpscorp.ca/

Contact:

Shirley Wong | Communications Manager

Phone: 604 232-4145 Ext. 1239

shirley.wong@fpscorp.ca

www.fpscorp.ca

FPS Food Process Solutions Brings in Symotab to Expand Compact, High Performing Coating Solutions for Protein and Snack Processors

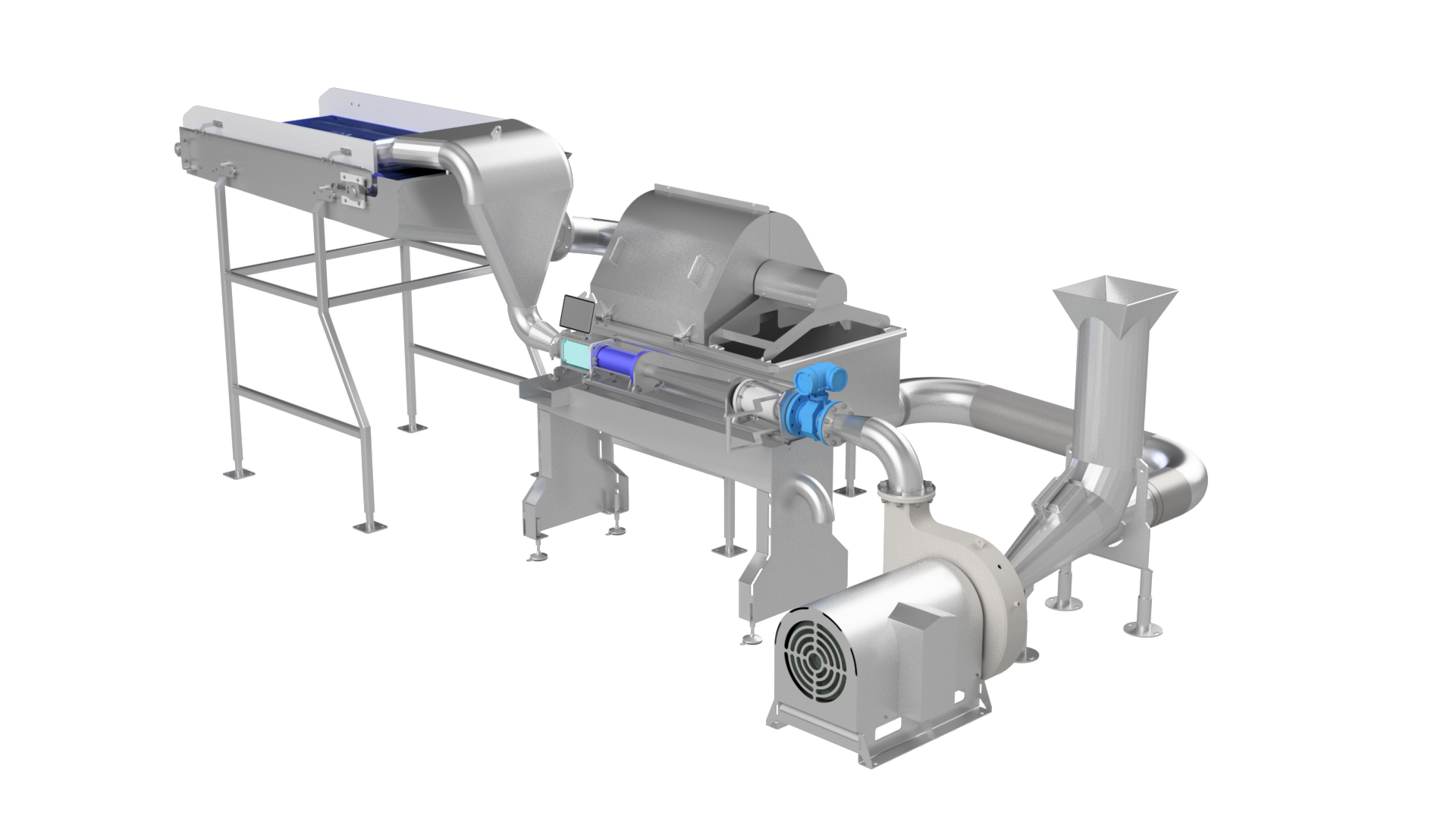

FPS+Symotab 3-in-1 CombiCoater

Vancouver, Canada – FPS Food Process Solutions (“FPS”), a global leader in turn-key food processing solutions, announces the addition of Symotab Kft, a specialist in advanced coating technology for protein and snack applications. Headquartered in Hungary, Symotab is known for the 3-in-1 CombiCoater, a compact coating system that integrates flatbed, drum breader and flip functionality into a single machine. Designed to reduce line length, simplify sanitation, and improve coating consistency, the CombiCoater addresses key challenges faced by modern food processors operating under increasing space, labor, and yield pressures.

This addition expands FPS’s portfolio of integrated processing solutions and strengthens its ability to offer flexible, space-efficient coating systems as part of complete processing lines for protein and snack producers worldwide.

“Joining FPS allows us to further develop and scale practical coating solutions that help processors save space, reduce complexity, and improve process stability,” says Ad Bontje, Managing Director, Symotab Kft. “Together with FPS, we are already working on next-generation solutions that support cleaner line layouts and more consistent coating performance.”

“We were impressed with the offering provided by Symotab – synergy, creativity, and the mindset to work together to build a solution. We welcome Symotab to the FPS family,” adds Jeffrey Chang, President, FPS Food Process Solutions Corp.

FPS + Symotab will showcase the 3-in-1 CombiCoater at the International Production and Processing Expo (IPPE) 2026 taking place January 27 – 29, 2026, at Booth C26143 in Atlanta, Georgia. For more information, visit https://info.fpscorp.ca/fps-ippe-2026

###

About FPS Food Process Solutions

FPS Food Process Solutions is a global leader in turn-key food processing solutions, serving customers across six continents. Founded in 2010, FPS employs over 1,000 professionals worldwide and operates more than 1,280,000 ft² (119,000 m²) of space across 23 locations, including its Canadian headquarters, manufacturing facilities, and international sales offices. Through our subsidiaries and strategic partnerships, FPS delivers comprehensive, end-to-end processing solutions—providing a true “one-stop shop” for food processors around the world.

For more information, go to https://www.fpscorp.ca/

Contact:

Shirley Wong | Communications Manager

Phone: 604 232-4145 Ext. 1239

shirley.wong@fpscorp.ca

www.fpscorp.ca

FPS Food Process Solutions and GEM Equipment of Oregon Launches VersaFry as Latest Collaborative Innovation to Target Growing Snack and Appetizer Market

Vancouver, Canada –FPS Food Process Solutions (“FPS”), a global leader in turn-key food processing solutions, and subsidiary GEM Equipment of Oregon (“GEM”), launches VersaFry as the latest collaborative innovation, specifically targeted to the growing snack and appetizer market. Known as GEM VersaFry, it is the latest innovation in fryer design – engineered for maintenance, safety and durability. With the ability to handle a variety of product shapes, consistencies and textures, the GEM VersaFry is excellent at handling specialty potato products, poultry, seafood, assorted vegetables, baked goods and other high value products requiring precision frying before further processing.

The GEM VersaFry offers Operation and Sanitation Modes, highlighting attention to detail such as oil quality, fire prevention safety measures and cleanability. Some of the key defining features include:

· PEEK/Teflon Adjustable Infeed Conveyor for smooth transfer and batter setting under high oil temperatures

· Long-Life Main Conveyor designed for easy splicing and reduced contamination risk

· Hood Raise Screw Jack System for full kettle access during sanitation and maintenance

· Oil Recirculation Pump to maintain oil level and temperature consistency

· Dual Crumb Removal with surface skimmer and bottom return belt for extended oil life

Every fryer is built with robustness and longevity as top priorities, to provide customers with the lowest cost of ownership. Combined with FPS’s foothold in key industry food sectors and established service and support network, the GEM VersaFry is already breaking ground in major food processing plants.

“GEM Equipment continues to astound – with their deep engineering expertise and robust workmanship, we are truly collaborative in every sense of the word. This is what it means to offer customers a “one-stop shop” for their food processing needs,” says Jeffrey Chang, President, FPS Food Process Solutions Corp.

###

About FPS Food Process Solutions

FPS Food Process Solutions is a global leader in turn-key food processing solutions, serving customers across six continents. Founded in 2010, FPS employs over 1,000 professionals worldwide and operates more than 1,280,000 ft² (119,000 m²) of space across 23 locations, including its Canadian headquarters, manufacturing facilities, and international sales offices. Through our subsidiaries and strategic partnerships, FPS delivers comprehensive, end-to-end processing solutions—providing a true “one-stop shop” for food processors around the world.

For more information about FPS, go to https://www.fpscorp.ca/

For more information about GEM, got to https://www.gemequipment.com/

Contact:

Shirley Wong | Communications Manager

Phone: (604) 232-4145 Ext. 1239

shirley.wong@fpscorp.ca

www.fpscorp.ca

FPS Food Process Solutions Targets Global Food Manufacturing and Technology Market with Major Expansions Around the World

FPS Global Food Innovation and Training Center

Vancouver, Canada – FPS Food Process Solutions (“FPS”), a global leader in turn-key food processing solutions, targets global food manufacturing and technology market with major expansion plans around the world. Key milestones include:

FPS MEA opens its 2nd location in central Morocco, to facilitate its logistics center to oversee equipment, parts and inventory for the Middle East and Africa region. The new location will be fully operational this month in January 2026.

GEM Equipment of Oregon, currently undergoing renovations to expand its Mt Angel, Oregon location, is expected to finish completion in Spring 2026. The 110,000 ft² (10,200 m²) space will accommodate manufacturing, spare parts, inventory and office space.

FPS Brazil, based in a major industrial technology site in São Paulo, will be able to offer manufacturing, spare parts and office space in its new 29,000 ft² (2,700 m²) location by Summer 2026.

FPS China recently held its ground-breaking ceremony in Zhongshan, Guangdong, China. Scheduled for completion in Autumn 2026, the 119,000 ft² (11,100 m²), nine-floor facility will incorporate an integrated food production platform, equipment R&D, global training center, and technological command center for real-time remote equipment monitoring.

FPS Europe is expected to complete expansion of its Goes, Netherlands facility to increase manufacturing capacity and inventory space totalling 61,000 ft² (5,700 m²) by end 2026.

“2026 will be a major year in implementing this new chapter of development for FPS — one where innovation, technology, manufacturing and full-scale production are fully coming together in key locations around the world. What was once an idea is turning into reality where industry professionals can make a difference, all to advance the future of food manufacturing,” says Jeffrey Chang, President, FPS Food Process Solutions Corp.

###

About FPS Food Process Solutions

FPS Food Process Solutions is a global leader in turn-key food processing solutions, serving customers across six continents. Founded in 2010, FPS employs over 1,000 professionals worldwide and operates more than 1,280,000 ft² (119,000 m²) of space across 23 locations, including its Canadian headquarters, manufacturing facilities, and international sales offices. Through our subsidiaries and strategic partnerships, FPS delivers comprehensive, end-to-end processing solutions—providing a true “one-stop shop” for food processors around the world.

For more information, go to https://www.fpscorp.ca/

Contact:

Shirley Wong | Communications Manager

Phone: (604) 232-4145 Ext. 1239

shirley.wong@fpscorp.ca

www.fpscorp.ca

FPS Food Process Solutions Expands Global Expertise in End-to-End French Fry Processing

Vancouver, Canada – FPS Food Process Solutions (“FPS”), a global leader in turn-key food processing solutions, strengthens its End-to-End platform with senior hires hailing from the potato processing sector. Joining the FPS team are:

Dave Rogers, Executive Director brings over 30 years experience in developing best operating practices and process optimization for multiple globally renowned potato processors. With his new role at FPS, Dave will support the End-to-End platform in providing strategic and in-depth technical guidance.

Mike Holden, Product Expert and Aftermarket Support, Special Projects brings over 40 years of hands-on experience in potato and vegetable processing. Mike’s deep operational knowledge and commitment to process optimization will bring valuable insights such as equipment design and development, sales team assistance, and comprehensive customer support through start-ups, troubleshooting, and aftermarket service.

Ronald Muller, Director, Special Projects brings 25 years of experience in project management, having worked for one of the largest potato processors in Europe to oversee capital projects such as plant setup and implementation. Based out of the Netherlands, Ronald will oversee End-to-End potato processing projects throughout the globe.

“We believe we can provide the best company support through the excellence of our team. FPS has always had our customers in mind, whether it be in-depth technical knowledge to process optimization to aftermarket support, we are with you every step of the way. At FPS, we offer solutions,” says Jeffrey Chang, President, FPS Food Process Solutions Corp.

-30-

ABOUT FPS FOOD PROCESS SOLUTIONS

FPS Food Process Solutions, a global leader in turn-key food processing solutions, employs over 1000 staff around the world. Established in 2010, FPS has a combined 1,180,000+ sq. ft (110,000 sq. meters) of space in 20 locations including its Canadian headquarters, manufacturing, and warehouse facilities as well as international sales offices across six continents. Joining the global FPS family are Charlottetown Metal Products (CMP), Total Solutions Ltd (TSL) and GEM Equipment of Oregon (GEM) as subsidiaries and OptiCept Technologies as a strategic partner in PEF technology, further diversifying the company’s product offering with a “one stop shop” to meet customers’ needs. For more information, go to www.fpscorp.ca

Contact:

Shirley Wong | Communications Manager

Phone: 604 232-4145 Ext. 1239

shirley.wong@fpscorp.ca

www.fpscorp.ca