FPS Manufacturing Execution System (MES)

The FPS MES Solution transforms food processing operations through intelligent, data-driven integration and real-time production insights. Our comprehensive MES platform empowers your team with advanced work order management, predictive maintenance scheduling, real-time asset monitoring, and actionable analytics. With an intuitive interface and full mobile accessibility, FPS delivers a “one stop shop” to meet customers’ needs, reduce costs, and drive continuous improvement across your entire production line.

Remote Monitoring System

MES Production Module

MES CMMS Module

MES Quality Control Module

MES Factory Intelligence

To complement our full range of food processing equipment, FPS delivers an MES software suite that connects machines, people, and data into one cohesive ecosystem. These tools give users the ability to monitor performance and drive continuous improvement through actionable insights.

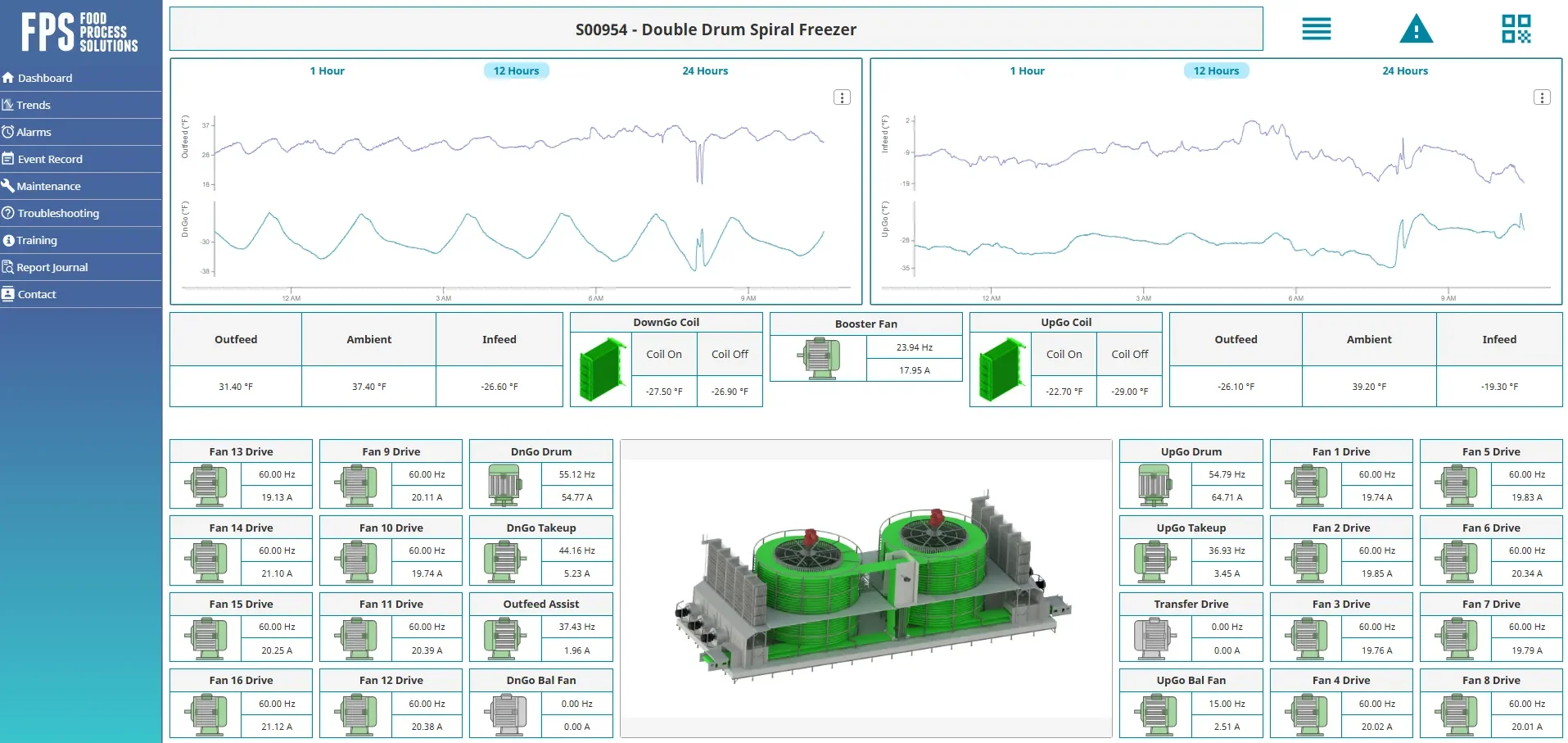

Remote Monitoring System

The FPS Remote Monitoring System is designed specifically for food processing operations. This system continuously tracks equipment performance metrics and transforms operational data into actionable insights for maintenance and production teams. The platform provides customizable dashboards for monitoring individual machine health, equipment utilization rates, and performance trends over time. Advanced analytics include predictive maintenance indicators and automated reporting for regulatory compliance. FPS Equipment Monitoring enables historical performance comparison analysis, helping teams identify optimization opportunities and prevent costly equipment failures while maintaining complete data security.

-

Real-Time Equipment Health Monitoring

Customizable Performance Dashboards

Predictive Maintenance Alerts

Long Term Data Storage

Automated Reporting

24/7 Support from Expert Technicians

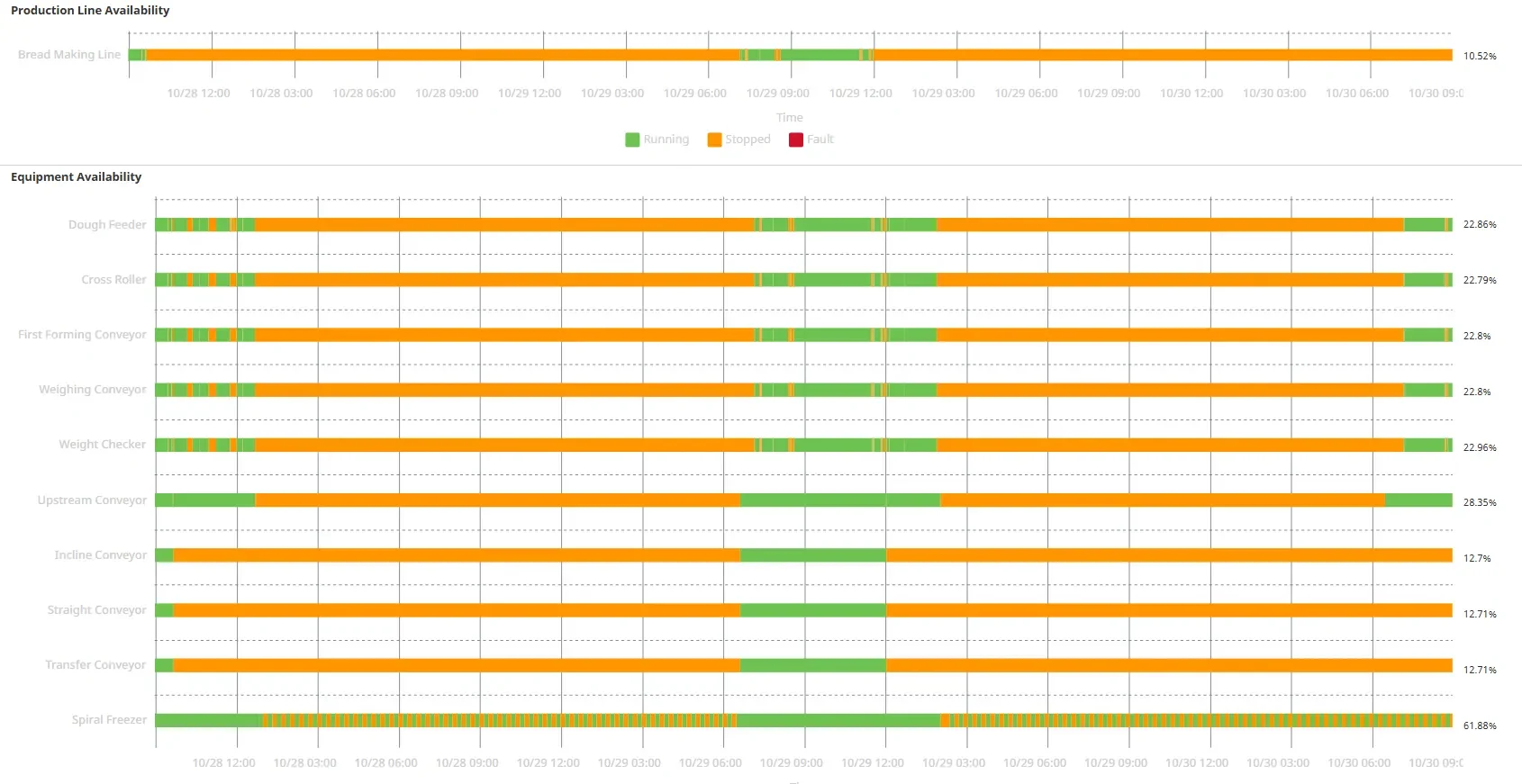

MES Production Module

The FPS MES Production Module provides a comprehensive view of overall line performance, enabling users to monitor production flow, efficiency, and throughput in real time. This module tracks key performance indicators such as OEE, downtime, and yield, giving operations teams the insights needed to identify bottlenecks and optimize productivity across the entire plant. Customized dashboards visualize production trends, compare shift performance, and evaluate equipment efficiency within the line. Analytics tools support continuous improvement by uncovering root causes of inefficiencies and providing data-driven recommendations for process optimization. The FPS MES Production Module ensures that every stage of production operates in harmony, maximizing uptime, product quality, and operational efficiency.

-

Unified IT/OT Integration

Bridges gap between enterprise systems and plant floor operationsScalable IoT Architecture

Handles unlimited tags and devices with distributed edge computing, enabling modular plant expansion and future-proof scalabilityWeb & Mobile Accessibility

Access plant data from any device, anywhere, with responsive interfacesNo Proprietary Protocols

Built on standard protocols including CIP, OPC-UA, MQTT, and REST API for secure and flexible communication

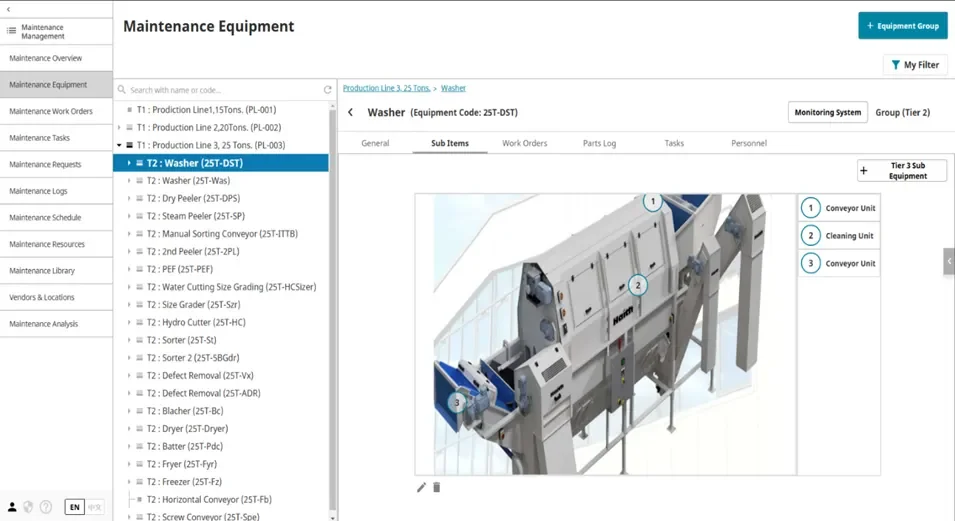

MES CMMS Module

Traditional maintenance management in food processing facilities faces significant operational hurdles that impact efficiency and uptime. The FPS MES CMMS Module solves two fundamental issues: the loss of invaluable maintenance knowledge when experienced workers retire or leave, and the scattered nature of maintenance records across multiple systems, documents, or individual memory. Our solution captures all that valuable maintenance knowledge in one central digital platform, giving you a single place to track every maintenance activity.

-

Knowledge Management & Transfer

Centralized documentation and step-by-step maintenance procedures prevent knowledge loss5-Tier Equipment Hierarchy

Structured asset management from production line level down to individual spare partsMaintenance History & Analytics

Complete audit trails track maintenance frequency, duration, and costs to optimize preventative maintenance schedules

Documentation & Parts Management

Instant access to maintenance manuals, technical drawings, or other necessary maintenance related documentation

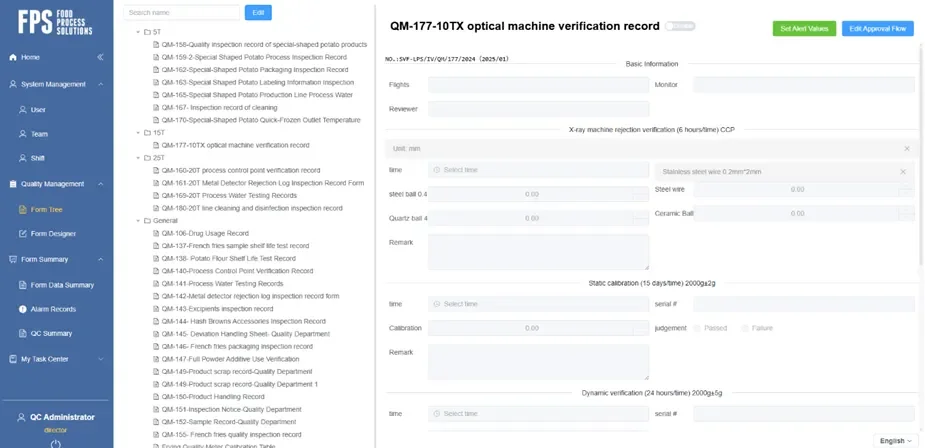

MES Quality Control Module

This Quality Control module delivers comprehensive digital quality management across your entire process - from task assignment and form creation to approval workflows, anomaly alerts, and intelligent reporting. The system enables dynamic QC form creation, allowing teams to design and deploy inspection forms that adapt to different products and processes. By unifying user roles and permissions, it ensures clear responsibilities and standardized data collection while reducing human errors. Multi-level electronic signatures and change tracking enforce compliance, while automated alerts trigger re-inspection tasks for rapid issue resolution. Managers gain access to real-time trend analysis, anomaly distribution charts, and AI-generated reports, enabling informed decision-making that significantly enhances quality control and operational efficiency.

-

Dynamic Form Builder

Create custom inspection forms that adapt to different products and processes with flexible templatesAutomated Compliance Workflow

Multi-level signatures, change tracking, and automated alerts ensure compliance and rapid issue responseAI-Powered Analytics & Reporting

Intelligent reporting provide actionable insights for quality decisions

MES Factory Intelligence Module

FPS Factory Intelligence consists of several add-ons that harnesses the power of artificial intelligence and machine learning to transform your processing operation into a truly smart manufacturing facility. Our advanced AI solutions work continuously in the background, analyzing data streams, detecting patterns, and providing intelligent insights that human operators might miss. These cutting-edge technologies integrate with your existing systems to deliver proactive problem-solving, automated quality assurance, and instant access to critical operational knowledge.

-

Feature Anomaly Detection

Leverages advanced machine learning algorithms to automatically identify unusual patterns and performance deviations in process data before they impact production.Intelligent Plant Assistant Chatbot

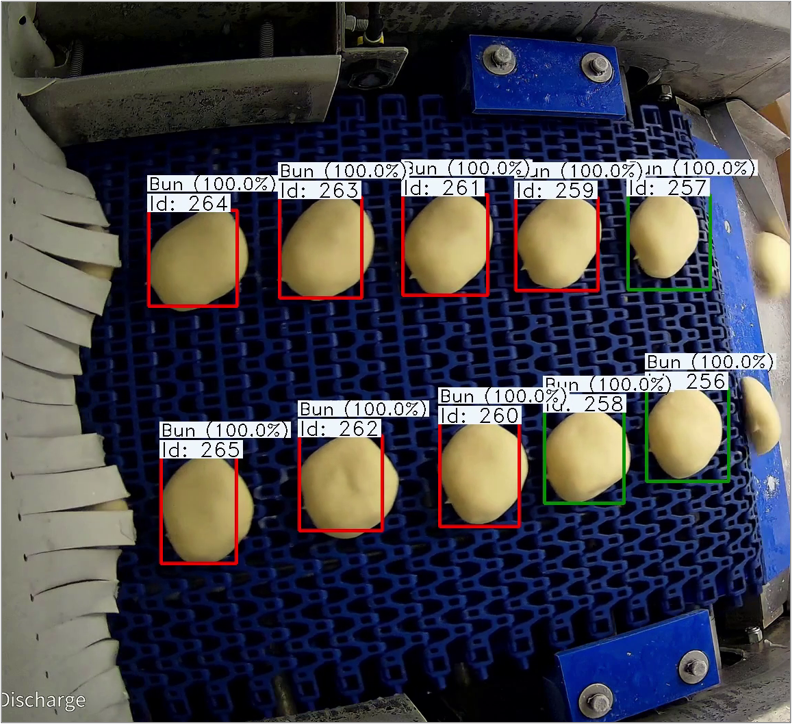

Provides operators and managers with real-time access to production insights, system status, and troubleshooting support through a conversational AI interface.Automated Quality Control Vision System

Uses high-speed imaging and AI-driven analysis to inspect products in real time, ensuring consistent quality and immediate detection of defects.