Coaters

Coaters

Our coating systems deliver flexible, high-quality solutions designed for modern protein and snack processing lines. At the heart of this innovation is the FPS + Symotab CombiCoater — a 3-in-1 system that combines Flatbed, Drum Breader, and Product Flip in one compact machine for predust, breadcrumb, and snack coating applications. This integration minimizes footprint, reduces cleaning effort, and lowers equipment count — all while maximizing uptime.

Supporting the CombiCoater are WizzCup viscosity monitoring and WizzConnect line management, giving operators:

Real-time insight into coating performance

Recipe-based configuration for fast, accurate changeovers

Coordinated control across conveyors and coating stations

Together, these solutions ensure consistent coating quality, smooth transitions, and predictable line performance across a wide range of protein and snack products. Engineered for convenience and reliability, our systems help processors achieve stable results with intuitive operation and integrated process control.

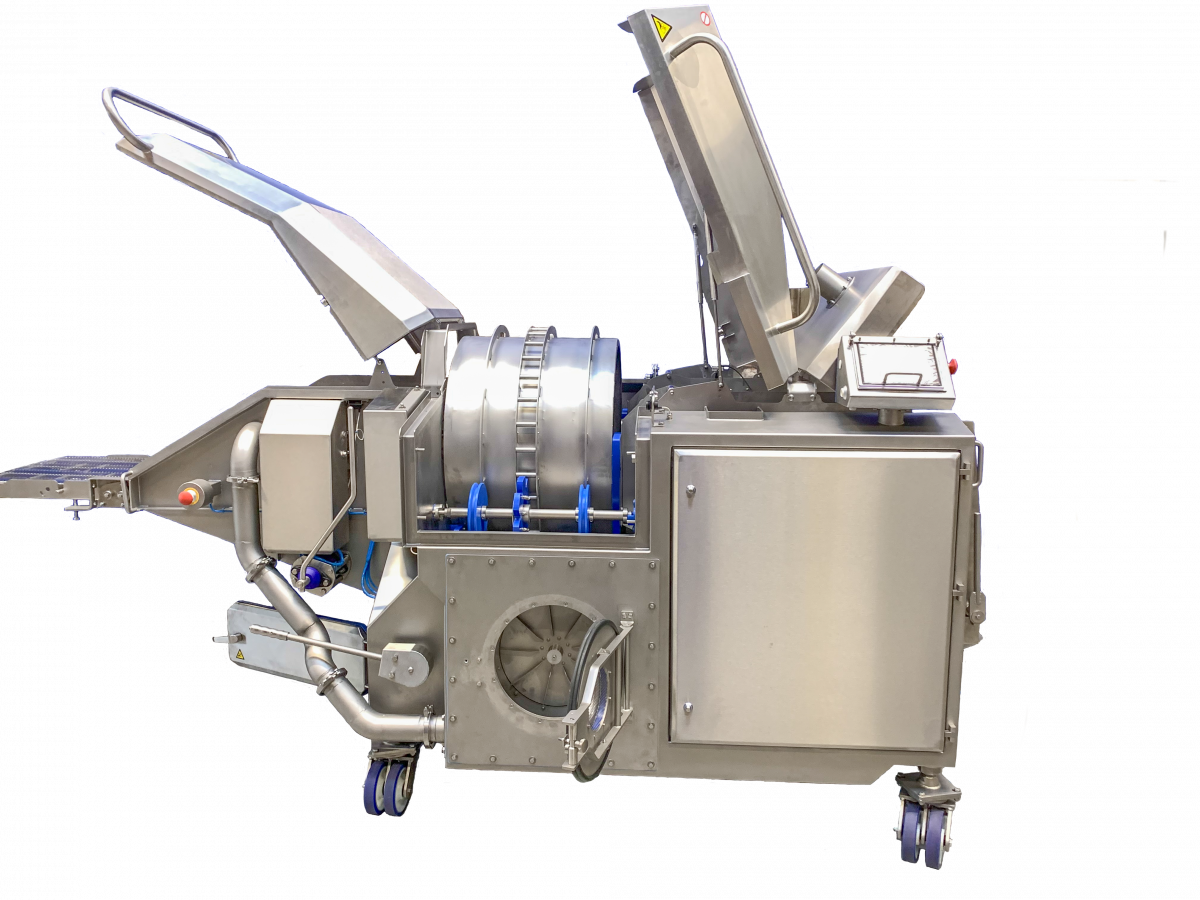

CombiCoater

The FPS + Symotab CombiCoater integrates a Flatbed, Drum Breader, and Flip into one robust system for predust and breadcrumb applications. It reduces footprint, equipment count, and cleaning time while enabling fast, tool-free changeovers to maximize uptime. Hygienic stainless-steel construction and an intuitive, language-free HMI simplify operation. The Cleaning Assist System (CAS) accelerates washdown, while real-time motor amp monitoring helps identify abnormal loads and minimize unplanned downtime across protein and snack lines.

Key Features

Available in 600mm and 1000mm standard belt widths adaptable to varied line capacities

Combination flatbed and drum modes in a single machine offers great flexibility – no need for separate machines – minimizing footprint and maximizing uptime

Scoop-based crumb handling helps preserve crumb quality, potentially improving final product appearance/texture