Fluid Removal Systems

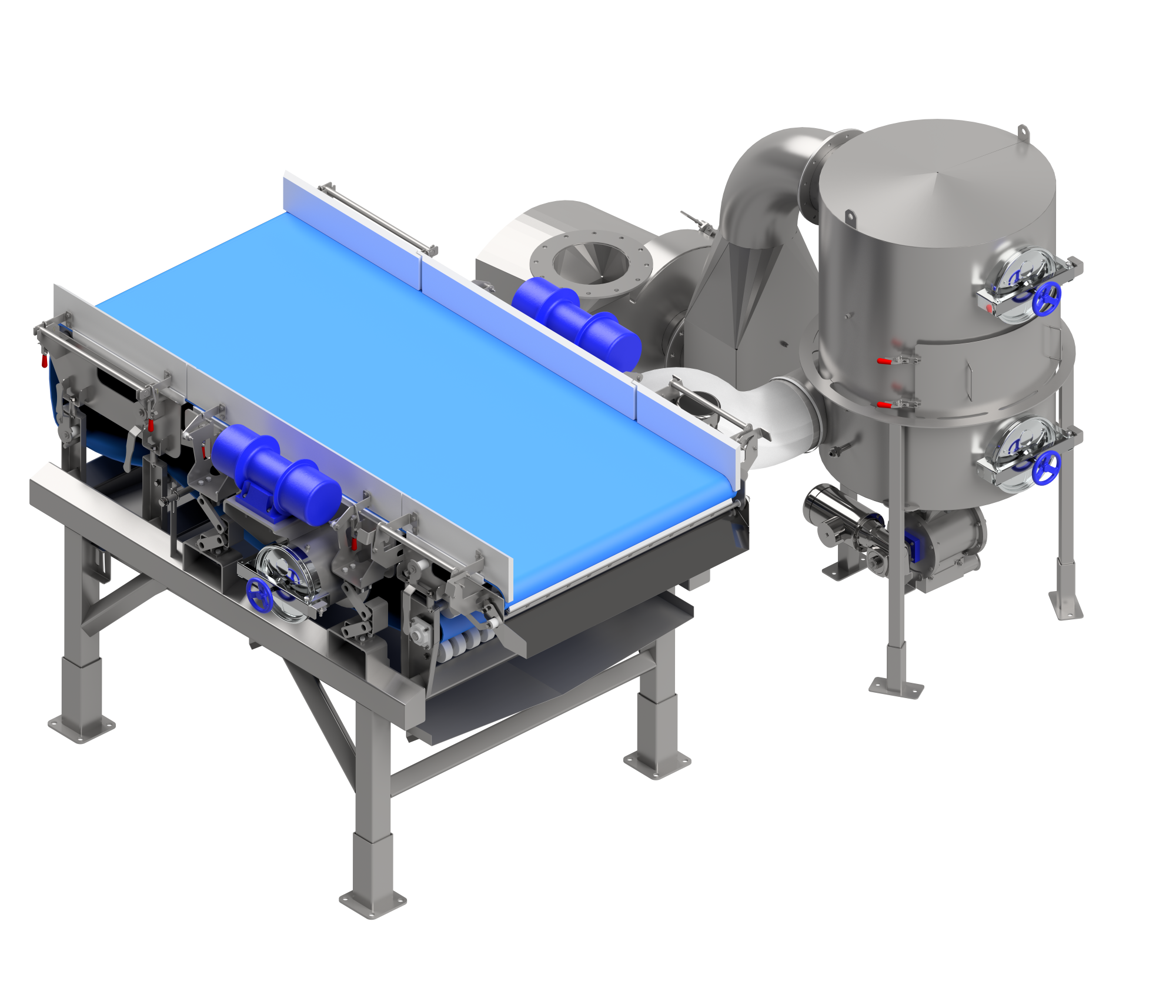

Fluid Removal System (FRS 2.0)

How Water Removal Can Boost IQF Tunnel Efficiency

Excess surface water entering a freezer can significantly impact freezer performance and product quality. Product surface water creates additional, non-product heat load that needs to be removed by the freezer’s refrigeration system. If not removed, excess water will freeze and either stick to products, causing clumping and dead-zones, or be blown into the coils causing blockages and decreasing production cycle times between defrost cycles.

The deployment of a fluid removal system can greatly enhance freezer efficiency by reducing surface water entering the freezer and ensuring product is spread evenly across the belt, resulting in longer production cycles, better freezing, and better product quality. That means getting more capacity out of existing IQF tunnels and increasing possible outputs for short production seasons.

Why Hygiene Matters in Fluid Removal Systems

Traditional dewatering systems provide no access to blowers or air paths and employ metal mesh belts that trap product debris. This results in trapped water, fines, and organic buildup in decks, plenums, or air ducts, which can become persistent contamination risks and can be blown back onto products. Accessibility for cleaning and inspection is therefore critical to mitigate contamination risks in these systems.

Key Benefits

Patented design combines vibratory force and high velocity air for maximum moisture removal

Up to 50% more water removal than competition

Best in Class Water Removal

Increase Freezer Throughput

Up to 15% increase in IQF tunnel capacity

Less product clumping in freezer

Ensures even bed depth and belt loading

Best in Class Hygiene

Ultra-hygienic perforated belting

Unrivaled accessibility to internals for cleaning

Optional CIP further improves cleanability

Key Features

Hygienic belting, lift-out side guides and belt lifters, and the cantilevered blower design offer unrivaled access for cleaning and inspection without the use of tools. Plenum and piping are covered by the Assisted Cleaning System (CIP), making the FRS 2.0 the most hygienic fluid removal system on the market.

Hygienic Design at its Best

Precise Control of Vibration, Retention, Suction

VFDs and adjustable blower exhausts allow for complete control of bed depth, vibratory force applied, suction pressure, and capture velocity. The resulting system is incredibly flexible, ensuring maximum moisture removal without damaging delicate products.

Belt Widths Match Production Needs

The FRS 2.0 offers a variety of belt widths to match your production line and ensure even product spread at freezer infeed, guaranteeing uniform bed depth and further improving freezing efficiency.