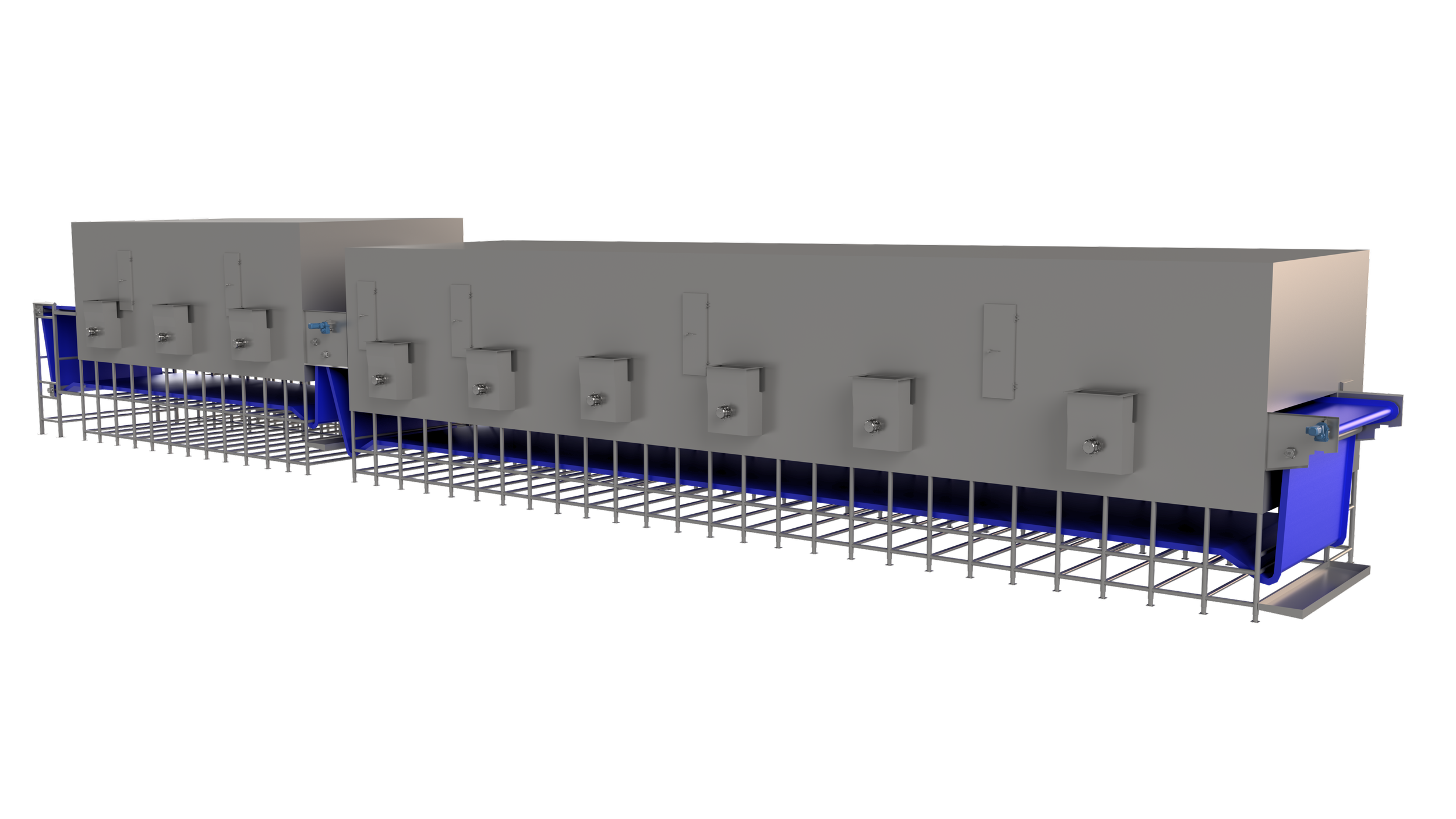

Dryer/Retrograder

FPS Dryer

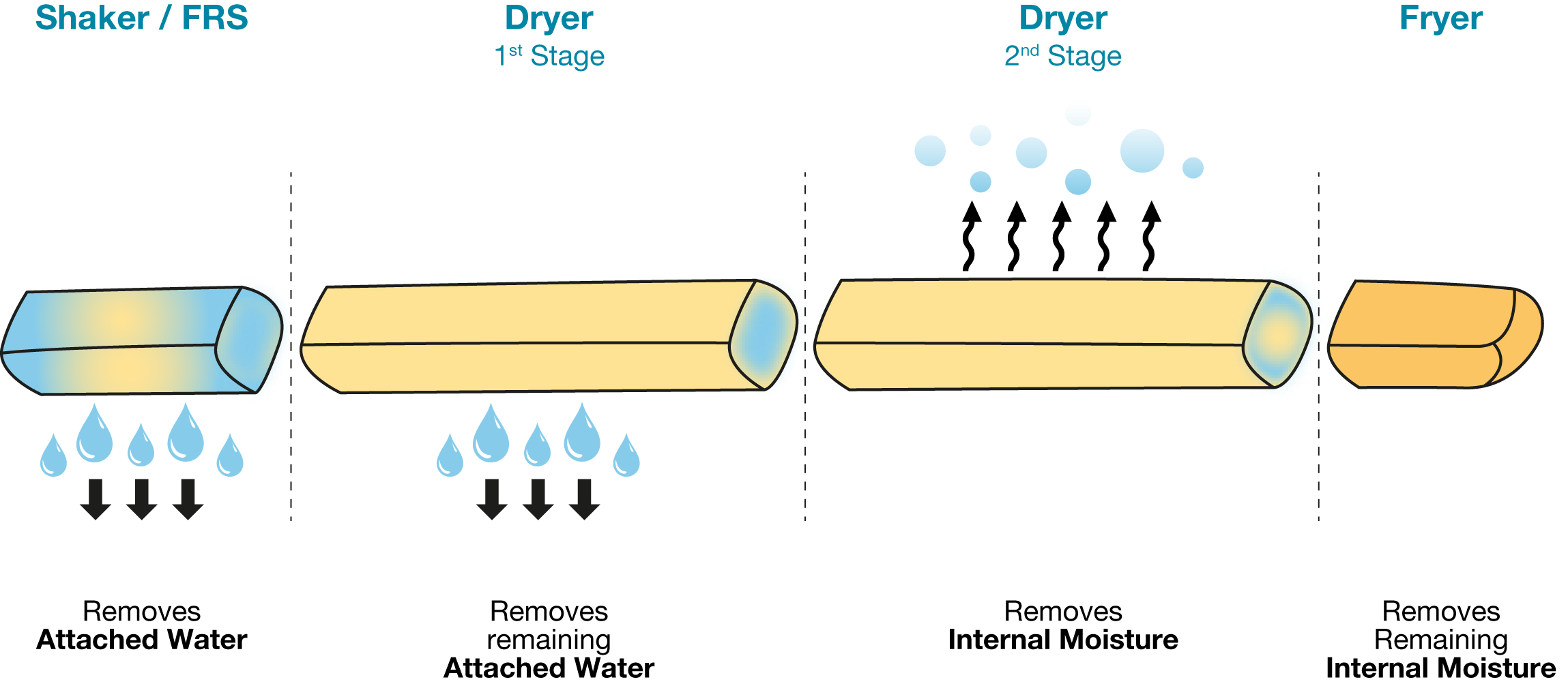

The process of drying is all about energy and moisture transport – remove surface water and remove internal moisture. For high quality products such as French Fries, it is important to have controlled drying conditions. If the product is dried too quickly, it dries out the external layer leaving behind a soggy interior after frying. Therefore, the multi-zone drying process is controlled through each stage, gently drying based on average dry solids per minute.

Features

Hygienic Design

Hygienic, fully welded stainless steel enclosure removes all potential harborage points

Externally mounted motors for blowers and belt drives removes conduit, junction boxes, wiring from the enclosure to enable best in class sanitation

Coils are vertically mounted with access on both sides for ease of sanitation

Embedded support structure within the fully welded walls allows for motors and gear boxes to be mounted on the outside of the enclosure – easier, safer maintenance access, extended service life, and improved sanitation

Slip-resistant fully welded sloped floors allow for effective drainage

BELTING TRANSFERABILITY

Hygienic plastic modular belting provides a non-stick surface for cleaner operation and ease of sanitation

The plastic modular belt is sprocket driven and does not require side chains that are utilized with metal belt solutions – greatly improving maintenance

Smaller head roll diameter (15 cm) allows transfers from one section to the next without chutes, eliminating product hang up/stickiness

HIGH PERFORMANCE AIR FLOW

Multi zone dryer solution removes attached water and internal moisture through gentle drying

With precision control of air velocity across the belt width, product is evenly distributed, resulting in uniform drying from end to end